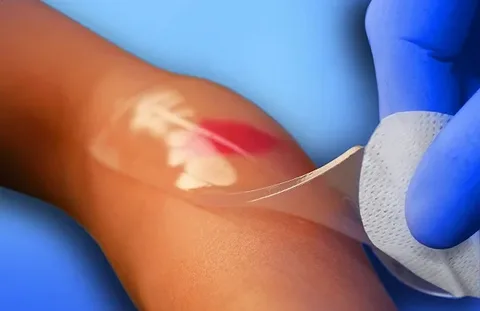

Wound care is an essential part of medical science, with billions invested annually to find ways to accelerate healing, reduce infections, and improve patient comfort. Among the latest advances in this field is the development of innovative wound dressings made from composite aerogels, composed of cellulose fibres and acid collagen.

These materials are increasingly recognized for their biocompatibility, superior mechanical properties, and ability to manage moisture—crucial attributes for efficient wound healing. This post explores the role of composite aerogels in the care, focusing on their unique properties, benefits, applications, and future potential.

1. The Importance of Innovative Wound Dressings

In recent years, medical research has focused on advanced materials to address wound-related challenges, including infection control, moisture regulation, and support for cellular regeneration.

Innovative wound dressings seek to go beyond traditional materials by integrating biocompatible and biodegradable composites that better mimic natural skin properties. This shift is especially significant given the high demand for advanced care in treating chronic wounds, post-surgical recovery, and diabetic ulcers. Composite aerogels, made from renewable sources like cellulose and collagen, are emerging as promising materials in this space.

Why Composite Aerogels?

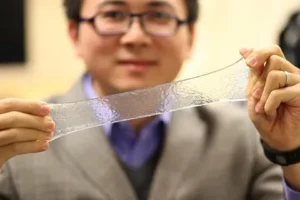

Composite aerogels stand out due to their unique structure—an ultra-lightweight, porous material that can absorb moisture and release it gradually, helping to maintain the ideal environment for healing.

The combination of cellulose fibres and acid collagen enhances the aerogel’s effectiveness by providing structural integrity and biological activity, which are essential for promoting tissue regeneration and reducing infection risk.

Key Benefits of Composite Aerogels in Wound Care

- Moisture Management: Composite aerogels have excellent water-absorbing properties, critical in creating a balanced wound environment.

- Antimicrobial Properties: Acid collagen offers natural antimicrobial benefits, reducing the need for added chemicals.

- Enhanced Healing Rates: The biocompatibility of these dressings supports faster healing by promoting cellular adhesion and migration.

- Comfort and Flexibility: The lightweight, flexible nature of aerogels improves patient comfort, especially in difficult-to-dress wound areas.

2. Exploring the Science Behind Cellulose Fibres and Acid Collagen

Cellulose and collagen are both naturally occurring polymers that serve as the foundation for numerous biomedical applications. Cellulose is derived from plant cell walls and is known for its mechanical strength, biodegradability, and non-toxicity. Collagen, on the other hand, is a protein found abundantly in animal connective tissues, essential for providing structure and elasticity to the skin.

Cellulose Fibres: The Structural Backbone

In the context of wound dressings, cellulose fibres play a pivotal role in providing the aerogel’s structural integrity. These fibres can be sourced sustainably from plants, offering a renewable base for creating medical-grade materials. Their strength and flexibility allow for durable, adaptable dressings suitable for various types, while their high absorbency helps in moisture control—a crucial factor in wound healing.

Acid Collagen: Promoting Healing and Reducing Infection

Acid collagen undergoes treatment with acidic solutions to enhance its biological activity and antimicrobial properties. When combined with cellulose fibres, it promotes cellular attachment, growth, and tissue regeneration.

Additionally, acid collagen’s antibacterial characteristics provide an added layer of protection against wound infections, a leading complication in wound management. By incorporating acid collagen, composite aerogels not only support structural needs but also actively contribute to faster and safer healing.

3. How Composite Aerogels are Manufactured

The production of composite aerogels involves multiple steps, each aimed at retaining the material’s biocompatibility and effectiveness. Typically, cellulose fibres and acid collagen are mixed in a solution, followed by a process called gelation where the mixture forms a gel. The next steps include freezing and lyophilization (freeze-drying), resulting in an ultra-lightweight, porous aerogel.

Key Manufacturing Steps

- Gelation: Cellulose fibres and acid collagen are dissolved in a solvent, mixed, and allowed to form a stable gel structure.

- Crosslinking: The gel is treated with crosslinking agents to enhance the bonding between cellulose and collagen, creating a cohesive, resilient structure.

- Freeze-Drying: The gel is frozen to remove solvents, leaving a highly porous and lightweight aerogel.

- Sterilization and Shaping: The aerogel is sterilized and shaped into dressings, ready for clinical application.

These steps are optimized to retain the biocompatibility and bioactivity of the aerogel, ensuring it can effectively support wound healing upon application. Furthermore, recent advancements in this process allow for the integration of other therapeutic agents within the aerogel, such as antimicrobial peptides or growth factors, to further enhance its healing potential.

4. Clinical Applications and Benefits of Composite Aerogel Dressings

Composite aerogels made from cellulose fibres and acid collagen have demonstrated remarkable performance in clinical settings. They are particularly beneficial in cases of chronic wounds and burns, where traditional dressings may fall short. Due to their tailored properties, composite aerogel dressings maintain optimal moisture, offer high absorbency, and provide comfort for extended wear, making them suitable for various wound types.

Chronic Wounds and Diabetic Ulcers

For patients suffering from chronic wounds or diabetic ulcers, managing infection risk and providing long-term care are critical. Composite aerogels are ideal for these applications due to their slow-release moisture capacity and inherent antibacterial properties from acid collagen. Studies have shown that these dressings can reduce healing times and lower infection rates, providing an innovative solution for complex wound care.

Surgical Wound Management

In post-surgical care, preventing infection and managing exudate (wound fluid) are essential. Composite aerogel dressings offer the dual benefit of absorbing excess fluid and reducing infection risk, thus supporting faster recovery. The flexibility of aerogels also allows for easier application to contoured body areas, making them suitable for various surgical sites.

Burns and Trauma Care

Burn injuries require dressings that can protect sensitive tissue, maintain moisture, and resist bacterial invasion. Composite aerogels meet these demands through their gentle adherence, antimicrobial properties, and high water content, which helps in maintaining the necessary moisture levels for burn recovery. Unlike traditional wound dressings, these aerogels do not cause additional trauma during dressing changes, minimizing patient discomfort.

5. Future Prospects: Innovations in Composite Aerogel Wound Dressings

The application of innovative wound dressings like composite aerogels from cellulose fibres and acid collagen marks a significant advancement in the field of regenerative medicine.

Research continues to explore ways to enhance these materials further, with potential improvements focusing on adding bioactive compounds, optimizing their structural characteristics, and developing dressings that can change properties in response to environmental cues (such as pH or temperature).

Bioactive Composite Aerogels

One area of active research is the integration of growth factors and antimicrobial peptides within the aerogel matrix to create a more bioactive composite aerogel. By embedding these agents directly into the dressing, future products could provide a continuous release of therapeutic compounds, further enhancing healing.

Smart Aerogels with Responsive Properties

Another promising innovation is the development of smart aerogels that can respond to changes in the wound environment. For example, a dressing that releases antibiotics in response to rising pH levels could prevent infections before they fully develop. Additionally, thermal-responsive dressings could provide targeted heating, accelerating the healing for certain injury types.

Sustainability and Scalability

With the global emphasis on sustainable development, producing these composite aerogels at a larger scale and from renewable resources is a priority. Leveraging sustainable production methods for cellulose extraction and reducing chemical processing in acid collagen production are critical steps to achieve a scalable, eco-friendly solution in advanced wound care.

Conclusion: A New Era in Wound Care with Composite Aerogels

The use of composite aerogels from cellulose fibres and acid collagen in wound dressings has opened up new possibilities for effective, sustainable, and comfortable wound care.

By combining the benefits of cellulose’s structural properties with collagen’s biological activity, these innovative dressings address key challenges in wound management, including infection control, moisture regulation, and patient comfort

. With advancements in bioactive integration and responsive properties, the future of composite aerogel dressings looks even more promising, aligning with the growing demand for sophisticated, patient-centric care solutions.

As we look ahead, it’s clear that composite aerogels will play an increasingly vital role in medical applications, setting a new standard for innovative wound dressings that not only heal but also protect, sustain, and promote regeneration in a variety of clinical settings. We invite you to share your thoughts on these exciting developments. Do you think composite aerogels might become the new standard in wound care? Share your comments below!