Introduction

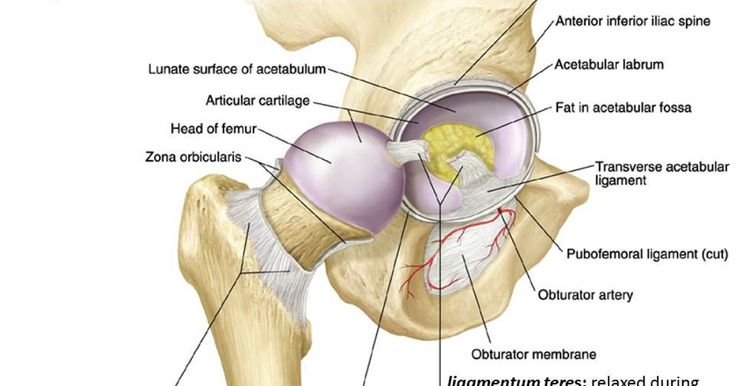

Hip joint osteoarthritis (OA) is a debilitating condition that affects millions of people worldwide, leading to pain, stiffness, and a reduced quality of life. This condition primarily results from the gradual wear and tear of cartilage within the hip joint, which serves as a cushion between bones.

As cartilage deteriorates, the bones begin to rub against each other, causing pain and restricting mobility. For many patients, the current treatment landscape involves pain management, physical therapy, or surgical interventions like total hip replacement. However, emerging technologies and materials, particularly polymers, are set to transform the way we approach hip joint osteoarthritis treatment.

Polymers, a class of materials made up of large molecular chains, have been gaining attention for their unique properties that could revolutionize the medical field. These materials have been used in various sectors, from packaging to electronics, but their potential in healthcare, particularly in treating osteoarthritis, is only beginning to be explored.

In this blog post, we will dive deep into how polymers can change the treatment landscape for hip joint osteoarthritis, offering new avenues for managing and potentially alleviating this chronic condition. We will also explore the science behind polymers, their potential applications in joint repair, and how they could improve patient outcomes in the future.

Understanding Polymers and Their Role in Medicine

Polymers are long chains of repeating molecular units, and their versatility has made them valuable across industries. They can be engineered to exhibit specific properties such as flexibility, strength, and biocompatibility, making them ideal candidates for medical applications. In fact, many of the materials used in medical devices today, from catheters to contact lenses, are made from polymers.

One of the most exciting areas of polymer research is in the development of biomaterials that can interact with the human body without causing adverse reactions. These biocompatible polymers can be used in drug delivery systems, tissue engineering, and, most notably, joint repair. When it comes to hip joint osteoarthritis, polymers offer several advantages over traditional materials used in joint replacement surgeries, such as metal and ceramic.

The ability of polymers to be engineered with precise mechanical and biological properties allows them to mimic natural cartilage more closely. This is crucial for osteoarthritis treatment because the goal is often to restore the smooth, lubricated surface that cartilage provides in the joint.

Polymers that can replicate this function may offer an alternative to full joint replacement, potentially delaying or even eliminating the need for invasive surgery. The use of polymers in this context has the potential to transform the treatment landscape for patients suffering from hip joint osteoarthritis by providing less invasive, more effective solutions.

Polymers in Joint Repair and Regeneration

One of the key ways in which polymers can transform the treatment landscape for hip joint osteoarthritis is through their application in joint repair and regeneration. Traditional treatments often focus on managing the symptoms of osteoarthritis rather than addressing the underlying causes. However, polymers offer a new approach by promoting the regeneration of damaged cartilage and potentially halting or reversing the progression of the disease.

Hydrogels, a type of polymer, have shown promise in cartilage repair due to their ability to hold large amounts of water and mimic the properties of natural cartilage. Hydrogels can be injected into the joint space, where they act as a scaffold for new tissue growth.

In some cases, they are combined with stem cells or growth factors to further enhance tissue regeneration. This approach could provide a non-surgical option for patients in the early stages of osteoarthritis, helping to preserve the joint and delay the need for more invasive treatments.

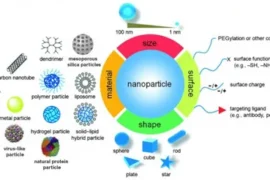

Furthermore, polymers can be engineered to deliver therapeutic agents directly to the affected area. For example, drug-loaded polymer nanoparticles can be injected into the joint, where they release anti-inflammatory or pain-relieving medications over time.

This targeted delivery system can reduce systemic side effects while providing long-lasting relief for patients with hip joint osteoarthritis. By focusing on both symptom management and tissue regeneration, polymers have the potential to significantly improve patient outcomes and transform the treatment landscape.

In addition to injectable treatments, polymers are being explored for use in developing bioresorbable implants. These implants can be designed to gradually break down in the body as they support tissue regeneration, eliminating the need for a second surgery to remove the implant. This innovation further highlights the versatility of polymers in hip joint osteoarthritis treatment, offering new possibilities for both early intervention and long-term care.

Polymers in Hip Joint Replacement

While non-surgical treatments are an exciting area of research, total hip replacement remains a common solution for advanced osteoarthritis. Traditionally, hip replacement surgery involves the use of metal or ceramic components to replace the damaged joint surfaces.

However, these materials, while durable, can lead to complications such as wear particles, which can cause inflammation and ultimately lead to implant failure. Polymers present a compelling alternative that could transform the treatment landscape for hip joint replacement by addressing some of these issues.

Highly cross-linked polyethylene (HXLPE) is one such polymer that has already made significant strides in hip replacement surgeries. HXLPE is a type of plastic that has been chemically treated to improve its wear resistance, making it an ideal material for joint replacement components.

The use of HXLPE in hip implants has been shown to reduce the wear rate of the implant, leading to longer-lasting results and fewer complications. As a result, patients can enjoy improved mobility and reduced pain for longer periods before needing revision surgery.

In addition to improving the longevity of hip implants, polymers can also enhance their biocompatibility. Advances in polymer coatings for implants have the potential to reduce the risk of infection and promote better integration with surrounding tissues.

By minimizing the body’s immune response to the implant, these coatings can improve the overall success rate of hip replacement surgeries. As research continues, it is likely that polymers will play an even more significant role in developing next-generation hip implants, further transforming the treatment landscape for hip joint osteoarthritis.

Another promising avenue of research is the development of smart polymers that can respond to changes in the body. For example, temperature-sensitive or pH-sensitive polymers could be used in hip implants to release anti-inflammatory drugs in response to inflammation, helping to reduce pain and improve recovery times. These intelligent materials represent the future of hip joint replacement, offering personalized treatment options that adapt to the patient’s needs.

The Future of Polymers in Osteoarthritis Treatment

As research into polymers continues to advance, the possibilities for transforming the treatment landscape for hip joint osteoarthritis are vast. One of the most exciting areas of development is the use of 3D printing technology to create custom polymer implants and scaffolds tailored to the individual patient’s anatomy. This personalized approach could lead to better outcomes and faster recovery times, as the implants would be designed to fit perfectly within the patient’s joint.

3D-printed polymer scaffolds could also be used to support the regeneration of cartilage and bone tissue, offering a long-term solution for patients with early-stage osteoarthritis. By combining 3D printing with advanced polymer materials, researchers hope to create implants that not only replace damaged tissue but also encourage the body to heal itself. This approach could fundamentally change the way we think about osteoarthritis treatment, shifting the focus from symptom management to true joint restoration.

In addition to 3D printing, there is growing interest in the use of bioactive polymers that can stimulate the body’s natural healing processes. These polymers could be designed to release growth factors, promote cell migration, and encourage the formation of new tissue. By harnessing the body’s own regenerative capabilities, bioactive polymers could offer a revolutionary approach to treating hip joint osteoarthritis.

As the understanding of polymer science deepens, the potential for new and innovative treatments will continue to grow. Whether through joint repair, drug delivery, or hip replacement, polymers have the potential to transform the treatment landscape for patients suffering from hip joint osteoarthritis. The future of osteoarthritis treatment is bright, with polymers at the forefront of this exciting new frontier.

Conclusion

The potential for polymers to transform the treatment landscape for hip joint osteoarthritis is immense. From joint repair and regeneration to improved hip replacement materials, polymers offer a wide range of applications that could significantly improve patient outcomes.

As research and development continue, we are likely to see even more innovative uses for polymers in the treatment of osteoarthritis, offering hope to millions of people living with this chronic condition.

Whether you are a patient, healthcare professional, or simply someone interested in medical advancements, the role of polymers in treating osteoarthritis is a topic worth watching closely. As we look to the future, the possibilities for transforming the way we treat hip joint osteoarthritis are endless, and polymers are set to play a central role in this transformation.

If you found this post informative or have any thoughts on the role of polymers in osteoarthritis treatment, feel free to leave a comment below. We’d love to hear your perspective!