Introduction

In the world of modern surgery, precision is paramount. Surgeons and medical professionals require tools and materials that support seamless healing while minimizing complications.

One such breakthrough in surgical materials is Polyglactin 910, commonly knownhttps://www.sciencedirect.com/topics/medicine-and-dentistry/polyglactin by its brand name, Vicryl. As a synthetic absorbable suture, Polyglactin 910 has become a gold standard for a wide array of surgical procedures, offering unparalleled strength, biocompatibility, and precision.

This blog explores the unique properties, applications, and benefits of Polyglactin 910, highlighting why it stands out in the competitive field of surgical sutures.

The Evolution of Surgical Sutures

Surgical sutures have played a pivotal role in medicine for centuries. Early sutures were derived from natural materials like silk, catgut, and horsehair. While effective for their time, these materials often posed challenges such as inconsistent absorption rates, allergic reactions, and risks of infection.

The advent of synthetic absorbable sutures, particularly Polyglactin 910, marked a turning point in surgical science. Developed to address the limitations of natural sutures, Polyglactin offers a combination of strength, predictability, and safety. This innovation allows surgeons to achieve optimal outcomes with enhanced surgical precision.

In this article, we’ll dive deeper into why Polyglactin 910 is widely regarded as the ideal synthetic absorbable suture.

1. What is Polyglactin 910?

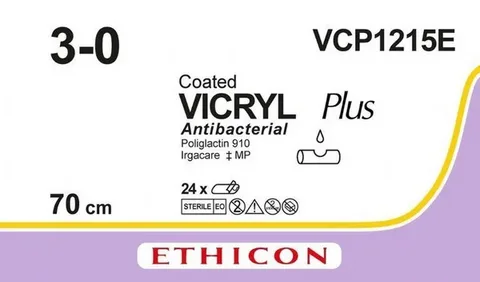

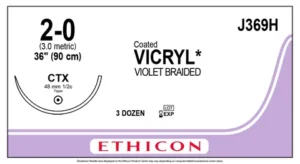

Polyglactin 910 is a synthetic, braided absorbable suture made from a copolymer of glycolide and lactide. It was introduced to the medical community under the trade name Vicryl by Ethicon, a subsidiary of Johnson & Johnson.

Key Characteristics of Polyglactin 910:

- Composition: Made from glycolide and lactide, two biodegradable polymers.

- Structure: Braided design for superior handling and knot security.

- Coating: Often coated with Polyglactin 370 or calcium stearate to reduce tissue drag.

- Absorption Rate: Fully absorbed within 56–70 days through hydrolysis, with approximately 50% tensile strength retained after two weeks.

Polyglactin’s design ensures excellent performance during the critical healing phase, making it suitable for procedures ranging from general surgery to ophthalmology and gynecology.

Advantages of Synthetic Absorbable Sutures

- Predictable Absorption: Unlike natural sutures, Polyglactin degrades in a controlled manner, reducing the risk of premature suture breakdown.

- Low Tissue Reaction: The synthetic material minimizes inflammatory responses, promoting smoother healing.

- Ease of Use: Its braided structure offers excellent knot security and ease of handling during surgery.

The versatility and reliability of Polyglactin 910 make it a preferred choice for surgeons aiming for precise results.

2. Applications of Polyglactin 910 in Modern Surgery

Polyglactin 910’s unique properties make it suitable for various surgical specialties. Its adaptability ensures surgeons can rely on it across diverse procedures.

General Surgery

In abdominal wall closures, bowel anastomoses, and soft tissue repairs, Polyglactin provides the tensile strength required to hold tissues together while they heal. Its absorption profile aligns perfectly with the time needed for tissue regeneration.

Obstetrics and Gynecology

Polyglactin 910 is frequently used in Cesarean sections, episiotomies, and uterine repairs. Its braided design ensures secure knots, while its synthetic nature reduces post-operative complications like infections or adverse tissue reactions.

Ophthalmology

Eye surgeries demand materials that are delicate yet reliable. Polyglactin is an excellent choice for closing conjunctival incisions, offering the precision and gentle handling needed for these sensitive procedures.

Orthopedics

For procedures such as tendon repairs or ligament reconstructions, Polyglactin provides robust support during the early healing stages, ensuring stability as tissues regain strength.

Pediatrics

Children’s surgeries require absorbable sutures to avoid the need for suture removal, which can be traumatic. Polyglactin is ideal due to its predictable absorption and minimal tissue reactivity.

In each of these fields, the characteristics of synthetic absorbable sutures like Polyglactin enable surgeons to achieve superior results with minimal complications.

3. Why Polyglactin 910 Excels in Surgical Precision

When it comes to surgical precision, the choice of suture material can significantly impact outcomes. Polyglactin 910 stands out for several reasons.

Braided Structure for Secure Handling

The braided design of Polyglactin allows surgeons to tie secure knots effortlessly. This reduces the risk of suture slippage during critical procedures, ensuring accurate tissue approximation.

Coated Surface for Reduced Tissue Drag

The proprietary coating on Polyglactin sutures minimizes friction, allowing smoother passage through tissues. This feature is especially beneficial in surgeries where delicate tissues are involved, such as vascular or ophthalmic procedures.

Predictable Absorption for Optimal Healing

One of the standout features of Polyglactin is its consistent absorption profile. The suture retains strength during the initial weeks when tissue healing is most critical, then gradually degrades, eliminating the need for removal.

Minimized Inflammatory Response

Natural sutures often provoke inflammatory reactions, which can hinder healing. As a synthetic absorbable suture, Polyglactin elicits minimal immune responses, ensuring a smoother recovery process.

Surgeons value Polyglactin for its reliability, handling, and the precision it brings to even the most demanding procedures.

4. Comparing Polyglactin 910 to Other Sutures

To understand why Polyglactin 910 is the preferred choice, it’s helpful to compare it with other types of sutures.

Polyglactin vs. Natural Sutures (e.g., Catgut)

- Durability: Catgut degrades unpredictably, while Polyglactin offers consistent tensile strength.

- Biocompatibility: Polyglactin causes less inflammation compared to natural sutures.

- Shelf Life: Synthetic sutures have a longer shelf life and are not as sensitive to storage conditions as natural sutures.

Polyglactin vs. Monofilament Sutures (e.g., Polydioxanone)

- Handling: Braided Polyglactin is easier to handle and tie than monofilament sutures.

- Applications: While monofilaments are preferred for vascular surgeries due to reduced infection risk, Polyglactin excels in soft tissue closures and general surgeries.

Polyglactin vs. Non-Absorbable Sutures (e.g., Nylon)

- Patient Comfort: Non-absorbable sutures require removal, which can be uncomfortable. Polyglactin absorbs naturally, reducing the need for follow-up procedures.

- Healing Dynamics: Polyglactin supports healing tissues without the prolonged presence of foreign material.

These comparisons highlight how Polyglactin balances the best of both worlds: the strength and reliability of non-absorbable sutures with the biocompatibility and convenience of absorbable options.

Conclusion: The Future of Surgical Sutures

As surgical techniques continue to advance, the tools and materials used must keep pace. Polyglactin 910 has proven to be an indispensable ally for surgeons, offering unmatched surgical precision through its strength, predictability, and biocompatibility.

Whether for routine procedures or complex surgeries, the role of synthetic absorbable sutures like Polyglactin is undeniable. By reducing complications, enhancing patient comfort, and enabling precise outcomes, these sutures represent the future of surgical care.

What are your experiences with Polyglactin 910? Do you see it as the ultimate solution for surgical precision? Let us know your thoughts in the comments below!