Introduction

The field of prosthetics has evolved from simple wooden and metal constructs to highly engineered devices designed for functionality and aesthetics. Thanks to cutting-edge developments in materials science, modern prosthetics now feature lightweight and durable components that can withstand the rigors of daily use while remaining comfortable for the wearer.

These advancements have been made possible by materials like carbon fiber, titanium, and medical-grade silicone, each offering distinct advantages for specific types of prostheses.

Understanding the best materials for prosthetics is crucial for engineers, healthcare professionals, and users alike. By examining how lightweight and durable components enhance the performance of modern devices, we can appreciate how far this field has come and where it is headed in the future.

1. Carbon Fiber: A Revolution in Prosthetic Design

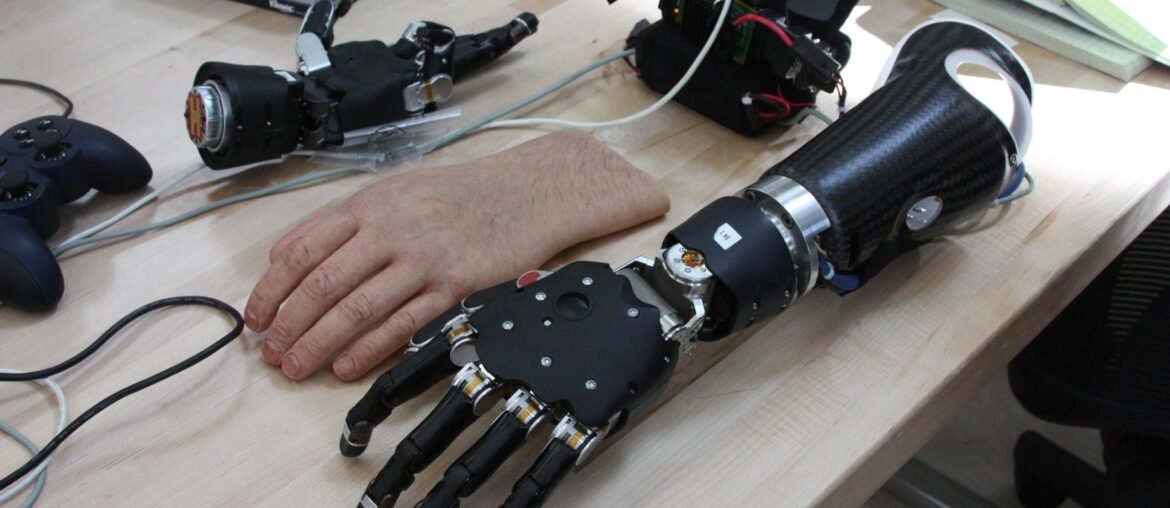

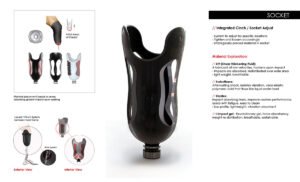

One of the most significant breakthroughs in the design of modern prosthetics has been the introduction of lightweight and durable components made from carbon fiber. This material is favored for its superior strength-to-weight ratio, making it ideal for both upper and lower limb prosthetics.

Benefits of Carbon Fiber

- Lightweight and Durable: Carbon fiber is much lighter than traditional metals like steel or aluminum, allowing for better mobility without sacrificing strength. This combination of qualities enables prosthetic users to perform more dynamic movements with less effort. Additionally, its durability ensures that it can withstand years of wear and tear without deteriorating.

- Energy Efficiency: One of the most notable benefits of carbon fiber prosthetics is their ability to store and release energy. This feature is particularly valuable in lower limb prosthetics, where the user’s gait and movement efficiency are critical.

- Customization and Versatility: Carbon fiber can be molded into a variety of shapes, making it highly customizable for each user’s unique needs. Whether it’s a running blade for athletes or a more traditional leg prosthesis for everyday use, carbon fiber’s adaptability makes it one of the best materials available.

However, despite these benefits, carbon fiber can be expensive to produce, which is why not all prosthetic devices use this material. Yet for those who can afford it, carbon fiber remains one of the most lightweight and durable components for modern prosthetics.

2. Titanium: The Gold Standard for Durability

While lightweight materials like carbon fiber are essential for mobility, durable components like titanium play an equally critical role in ensuring that modern prosthetic devices are robust and long-lasting. Titanium has long been regarded as the gold standard for structural strength in medical applications, including prosthetics.

Why Titanium is a Popular Choice

- Strength and Corrosion Resistance: Titanium is incredibly strong and resistant to corrosion, making it ideal for prosthetics that need to withstand harsh environments or extended wear. This is especially important for lower-limb prosthetics, which are exposed to more impact and friction than upper-limb devices.

- Biocompatibility: Titanium is also biocompatible, meaning it can be safely integrated into the body without causing adverse reactions. This makes it a preferred material for osseointegrated prosthetics, where the prosthetic device is anchored directly into the bone.

- Lightweight: Despite its strength, titanium is relatively lightweight compared to other metals, making it more comfortable for the user. This balance of strength and weight makes titanium one of the best materials for prosthetics designed for long-term use.

However, titanium’s cost can be prohibitive for some patients. Despite this, its durability and lightweight nature make it an indispensable material in high-performance prosthetic limbs, especially for individuals seeking modern devices that offer both comfort and resilience.

3. Medical-Grade Silicone: Enhancing Comfort and Functionality

While materials like carbon fiber and titanium provide structural support, medical-grade silicone has become the go-to material for soft tissue components in modern prosthetics. This lightweight and flexible material is frequently used in areas that come into direct contact with the skin, such as liners, sleeves, and even cosmetic covers.

Key Advantages of Medical-Grade Silicone

- Softness and Flexibility: Silicone is soft and flexible, making it ideal for providing a cushion between the prosthetic and the skin. This is particularly important in reducing irritation and discomfort, which can occur with more rigid materials.

- Durable and Hypoallergenic: Despite its softness, silicone is highly durable and can withstand daily use without breaking down or causing skin reactions. Its hypoallergenic properties make it suitable for individuals with sensitive skin or allergies.

- Realistic Appearance: Silicone can be colored and textured to mimic real skin, offering an aesthetic option for those who prioritize the look of their prosthetic limb. This adds to the emotional and psychological well-being of the user, making silicone a highly versatile component in modern devices.

Silicone’s unique combination of comfort and durability makes it one of the best materials for the soft, external components of prosthetics. Its role in enhancing both the functionality and aesthetics of prosthetic limbs cannot be overstated.

4. Plastics and Composites: Balancing Cost and Performance

Not all prosthetic devices require high-end materials like carbon fiber or titanium. For more cost-effective solutions, various plastics and composite materials offer a balance between performance and affordability.

These lightweight and durable components are often used in pediatric prosthetics or devices for individuals who require less mechanical stress on their prosthetic limbs.

Advantages of Plastics and Composites

- Affordability: One of the primary advantages of using plastics and composites in prosthetics is their lower cost. While these materials may not offer the same level of strength as titanium or carbon fiber, they provide a viable alternative for those who need functional but budget-friendly options.

- Lightweight: Plastics are incredibly lightweight, which can make them more comfortable for users who may not need the structural integrity provided by more expensive materials. For example, some upper-limb prosthetics can be made entirely from plastics without sacrificing function.

- Customizability: Similar to carbon fiber, plastics and composites can be easily molded to fit the specific needs of the user. This makes them versatile options for creating both functional and aesthetically pleasing modern devices.

While plastics and composites may not be as durable as their more expensive counterparts, they still offer a reliable and affordable solution for many prosthetic users. These materials continue to play an essential role in expanding access to prosthetics for individuals worldwide.

Conclusion

The evolution of modern prosthetic devices has been driven by the development of lightweight and durable components that enhance both functionality and user comfort. From the unparalleled strength of carbon fiber to the biocompatibility of titanium and the comfort of medical-grade silicone, each material offers unique advantages that contribute to the overall effectiveness of the prosthetic.

Choosing the best materials for prosthetics depends on various factors, including the specific needs of the user, the type of prosthetic limb, and budget considerations. As materials science continues to advance, we can expect even more innovations that will make prosthetics lighter, stronger, and more comfortable for users worldwide.

We invite you to leave a comment below: What material do you think holds the most promise for the future of prosthetic development? Do you have personal experiences with any of these materials? We’d love to hear your thoughts!