Introduction

Polymer science has traditionally relied on a combination of empirical knowledge, trial-and-error experimentation, and theoretical modeling to innovate and enhance materials. However, the advent of Machine Learning (ML) has ushered in a new era of possibilities, fundamentally transforming the way scientists approach molecular structure design and material performance enhancement.

As industries ranging from aerospace to biomedicine seek increasingly sophisticated materials, the integration of ML into polymer science offers unprecedented opportunities for innovation and efficiency.

This post will delve into the transformative impact of ML on polymer science, focusing on how it aids in the design of molecular structures and enhances material performance.

Revolutionizing Molecular Structure Design with Machine Learning

1. Accelerating the Discovery Process

The traditional process of designing new polymers involves generating and testing numerous potential molecular structures to identify those with desirable properties. This approach is time-consuming and resource-intensive, often requiring years of research and development.

Machine Learning revolutionizes this process by enabling the rapid analysis of vast datasets, thereby identifying patterns and predicting the properties of novel molecular structures.

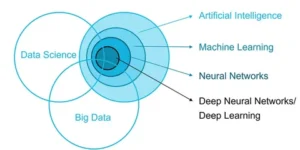

Machine Learning algorithms, such as neural networks and decision trees, can be trained on existing data to learn the relationships between molecular structure and material properties. By analyzing thousands of molecular configurations, ML models can predict which structures are likely to yield materials with specific characteristics, such as high tensile strength, thermal resistance, or biocompatibility.

This capability drastically reduces the time required to identify promising candidates for further experimentation, thus accelerating the overall discovery process.

Moreover, ML models can explore a broader range of chemical space than traditional methods. While human researchers might focus on known chemistries and proven methods, ML can uncover unconventional molecular structures that may have been overlooked due to their complexity or perceived improbability.

This opens up new avenues for innovation in polymer science, allowing for the development of materials with novel properties that were previously unattainable.

2. Enhancing Predictive Accuracy in Molecular Design

One of the most significant contributions of Machine Learning to polymer science is its ability to enhance predictive accuracy. In the context of molecular structure design, accurate predictions of material properties are crucial for minimizing trial-and-error experimentation.

Machine Learning models, particularly those utilizing deep learning techniques, have demonstrated remarkable accuracy in predicting a wide range of material properties based on molecular structure.

For example, ML models can predict the mechanical properties, thermal stability, and chemical resistance of polymers with high precision. This is achieved by training the models on large datasets that include various molecular structures and their corresponding properties.

The models then learn to associate specific structural features with material performance, enabling them to predict how a new polymer will behave based solely on its molecular structure.

Furthermore, these models can be continuously updated and refined as new data becomes available, leading to progressively more accurate predictions over time. This iterative learning process is a significant advantage over traditional methods, which often require manual recalibration and can struggle to keep pace with the rapid advancement of materials science.

Machine Learning and Material Performance Enhancement

3. Optimizing Polymer Performance Through Data-Driven Approaches

Once a polymer with a desirable molecular structure is identified, the next challenge lies in optimizing its performance for specific applications. This is where Machine Learning truly shines. By analyzing performance data from existing materials, ML algorithms can identify the key factors that influence material performance and suggest ways to enhance it.

For instance, ML can be used to optimize the processing conditions of polymers, such as temperature, pressure, and curing time, to achieve the best possible performance. Additionally, it can help in fine-tuning the molecular structure itself, suggesting slight modifications that could lead to significant improvements in properties like elasticity, toughness, or environmental resistance.

This data-driven approach allows for a more targeted and efficient optimization process. Instead of relying on broad, general principles, researchers can leverage specific insights generated by ML models to make precise adjustments that yield tangible improvements in material performance.

This capability is particularly valuable in high-stakes industries like aerospace or medical devices, where even minor enhancements can have a significant impact on safety, durability, and overall effectiveness.

4. Facilitating the Development of Multifunctional Polymers

The demand for multifunctional materials—those that can perform multiple functions simultaneously—is growing across various industries. Machine Learning is playing a pivotal role in the development of such materials by enabling the simultaneous optimization of multiple properties within a single polymer.

Traditionally, improving one property of a polymer often came at the expense of another. For example, increasing a polymer’s toughness might reduce its flexibility, or enhancing its thermal stability might compromise its processability. Machine Learning, however, can analyze complex datasets to identify molecular structures that optimize multiple properties simultaneously.

Through techniques like multi-objective optimization, ML models can balance trade-offs between competing properties and suggest molecular designs that achieve the best possible performance across all desired metrics.

This capability is particularly valuable in applications like flexible electronics, where materials must be both mechanically robust and electrically conductive, or in medical implants, which require a balance of biocompatibility, strength, and biodegradability.

The Future of Polymer Science with Machine Learning

5. Integrating Machine Learning into the Research Pipeline

As Machine Learning continues to mature, its integration into the polymer research pipeline will become increasingly seamless. Researchers are already developing automated systems that combine ML models with high-throughput experimentation techniques, allowing for the rapid testing and refinement of new polymers.

These integrated systems can operate almost autonomously, identifying promising molecular structures, predicting their properties, synthesizing the corresponding polymers, and testing their performance—all with minimal human intervention.

This represents a significant shift from the traditional research model, where each of these steps was typically handled by different specialists working in isolation.

By integrating Machine Learning throughout the research pipeline, the development of new polymers can be accelerated dramatically, potentially reducing the time from initial concept to marketable product from years to months.

This will be particularly beneficial in industries where the demand for new materials is driven by rapidly evolving technological trends, such as electronics, energy storage, and sustainable packaging.

6. Addressing Challenges and Ethical Considerations

While the benefits of Machine Learning in polymer science are clear, there are also challenges and ethical considerations that must be addressed. One major challenge is the quality and diversity of the data used to train ML models.

Inaccurate or biased data can lead to incorrect predictions and suboptimal material designs. To mitigate this risk, it is essential to curate high-quality datasets and ensure that they are representative of the full range of possible molecular structures and material properties.

Additionally, the increasing reliance on Machine Learning raises questions about the transparency and interpretability of the models used. In some cases, ML models, particularly deep learning models, can function as “black boxes,” making decisions based on complex internal processes that are difficult for humans to understand.

This lack of transparency can be problematic in high-stakes applications where understanding the rationale behind material design choices is crucial.

To address these concerns, researchers are developing explainable AI techniques that aim to make ML models more transparent and their predictions more interpretable. By ensuring that these models are both accurate and understandable, scientists can confidently apply ML to the design of new polymers while maintaining a clear understanding of the underlying principles.

Conclusion

The integration of Machine Learning into polymer science represents a paradigm shift in the way molecular structures are designed and material performance is enhanced. By leveraging the power of ML, researchers can accelerate the discovery process, enhance predictive accuracy, optimize material performance, and develop multifunctional polymers with unprecedented efficiency.

As this technology continues to evolve, it will undoubtedly play an increasingly central role in the advancement of polymer science, driving innovations that were once unimaginable.

However, the journey is far from over. As with any transformative technology, challenges remain, and ethical considerations must be addressed. The future of polymer science will depend not only on the continued development of Machine Learning techniques but also on the responsible and transparent application of these tools.

We invite you to join the conversation. What are your thoughts on the impact of Machine Learning on polymer science? How do you see this field evolving in the coming years? Leave a comment below and share your insights!