Introduction

Medical implants have revolutionized healthcare, offering solutions to a variety of medical conditions and enhancing the quality of life for millions of people worldwide. These devices, which can be implanted into the human body, range from pacemakers and artificial joints to stents and dental implants. One of the key factors driving the evolution and success of medical implants is the use of polymers. Polymers, with their diverse properties and adaptability, have opened new frontiers in the design and functionality of medical implants. In this blog post, we will explore the innovative ways in which polymers are transforming the future of medical implants, the benefits they offer, and the challenges faced in their application.

The Role of Polymers in Medical Implants

Biocompatibility and Versatility

Polymers are a class of materials that consist of long chains of repeating molecular units. Their unique chemical structure allows for a high degree of customization, making them suitable for a wide range of medical applications. One of the primary reasons polymers are favored in medical implants is their biocompatibility. This means that they can interact with human tissues without eliciting adverse reactions, such as inflammation or rejection. This property is crucial for the success and longevity of implants.

Moreover, the versatility of polymers allows them to be engineered with specific mechanical properties, such as flexibility, strength, and elasticity. This adaptability makes them ideal for creating implants that can mimic the natural behavior of body tissues. For instance, polymers used in joint replacements can be designed to withstand the mechanical stresses of movement, while those used in cardiovascular implants can be tailored to endure the pulsatile nature of blood flow.

Innovations in Polymer-Based Medical Implants

In recent years, there have been significant advancements in the development of polymer-based medical implants. Researchers are continuously exploring new polymer formulations and manufacturing techniques to enhance the performance and functionality of these devices. One notable innovation is the use of biodegradable polymers. These materials can gradually break down in the body, eliminating the need for a second surgery to remove the implant. This is particularly advantageous in applications such as drug delivery systems, where the implant can slowly release medication over time and then dissolve harmlessly.

Another exciting development is the incorporation of smart polymers. These materials can respond to environmental stimuli, such as changes in temperature, pH, or electric fields. Smart polymers can be used to create implants that deliver drugs in a controlled manner, adjust their properties in response to physiological conditions, or even self-heal minor damages. These capabilities open up new possibilities for personalized and adaptive medical treatments.

Types of Polymer-Based Medical Implants

Cardiovascular Implants

Cardiovascular diseases are a leading cause of death worldwide, and medical implants play a crucial role in their management. Polymers are widely used in the design of cardiovascular implants, such as stents, grafts, and heart valves. For example, drug-eluting stents, which are coated with a polymer that slowly releases medication, have significantly improved the outcomes of angioplasty procedures by reducing the risk of restenosis (re-narrowing of the artery).

Polymers also enable the creation of flexible and durable vascular grafts, which are used to bypass blocked or damaged blood vessels. These grafts can be engineered to mimic the natural elasticity and strength of blood vessels, ensuring seamless integration with the circulatory system. Additionally, polymer-based heart valves offer a durable and biocompatible alternative to traditional metal or tissue valves, reducing the risk of complications and extending the lifespan of the implant.

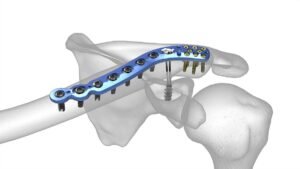

Orthopedic Implants

Orthopedic implants are used to replace or support damaged bones and joints, providing patients with improved mobility and pain relief. Polymers are extensively used in the design of orthopedic implants due to their lightweight nature and ability to mimic the mechanical properties of natural bone. For instance, polymer-based joint replacements, such as hip and knee implants, offer excellent wear resistance and durability, ensuring long-term functionality.

Furthermore, polymers are employed in the development of bone scaffolds for tissue engineering. These scaffolds provide a framework for the growth of new bone tissue, facilitating the healing of fractures and defects. Biodegradable polymers are particularly useful in this context, as they gradually degrade and are replaced by the newly formed bone, eliminating the need for additional surgeries.

Dental Implants

Dental implants are another area where polymers have made a significant impact. These implants are used to replace missing teeth, providing patients with improved aesthetics and functionality. Polymers are used in various components of dental implants, including the abutment (the connector between the implant and the artificial tooth) and the crown (the visible part of the implant). Polymer-based dental abutments offer excellent biocompatibility and can be customized to match the color and appearance of natural teeth.

In addition, polymers are used in the development of dental membranes and scaffolds for guided tissue regeneration. These materials promote the growth of new bone and gum tissue around the implant, ensuring a stable and long-lasting integration. Biodegradable polymers are particularly advantageous in this application, as they eliminate the need for a second surgery to remove the membrane once the tissue has regenerated.

Neurological Implants

Neurological implants, such as deep brain stimulators and cochlear implants, are used to treat a variety of neurological disorders and sensory impairments. Polymers play a crucial role in the design and fabrication of these implants, offering flexibility, biocompatibility, and electrical conductivity. For example, polymer-based electrodes used in deep brain stimulators can conform to the intricate structures of the brain, providing precise and targeted stimulation.

Moreover, polymers are used in the encapsulation of electronic components in cochlear implants, ensuring protection from the harsh environment of the inner ear. The flexibility of polymers allows for the creation of thin and lightweight implant components, improving patient comfort and reducing the risk of complications. Additionally, smart polymers with shape-memory properties are being explored for the development of minimally invasive neurological implants, which can change shape in response to body temperature and facilitate easier implantation.

Challenges and Future Directions

Biocompatibility and Longevity

While polymers offer numerous advantages in the design of medical implants, there are still challenges that need to be addressed to ensure their long-term success. One of the primary concerns is the biocompatibility of polymers over extended periods. Although many polymers are initially biocompatible, their interaction with body tissues can change over time due to factors such as degradation, wear, and the accumulation of by-products. This can lead to inflammation, infection, or implant failure.

To overcome these challenges, researchers are exploring various strategies, such as the development of new polymer formulations with improved biocompatibility and the use of surface modifications to enhance the interaction between the implant and surrounding tissues. Additionally, advanced imaging and diagnostic techniques are being employed to monitor the performance of polymer-based implants in real-time, allowing for early detection of potential issues and timely interventions.

Manufacturing and Regulatory Hurdles

The manufacturing of polymer-based medical implants involves complex processes that require precision and consistency to ensure the safety and efficacy of the final product. This includes the synthesis of polymers, fabrication of implant components, and assembly of the device. Each step must be carefully controlled to meet stringent regulatory standards set by health authorities, such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA).

One of the challenges in this regard is the scalability of manufacturing processes. While it is relatively easy to produce small quantities of polymer-based implants for research and development purposes, scaling up production to meet commercial demands requires significant investments in infrastructure and quality control systems. Furthermore, obtaining regulatory approval for new polymer-based implants can be a lengthy and expensive process, involving extensive preclinical and clinical testing to demonstrate their safety and efficacy.

Future Directions

Despite these challenges, the future of polymer-based medical implants looks promising, with ongoing research and development paving the way for new innovations. One of the emerging trends is the use of additive manufacturing (3D printing) to create customized implants with complex geometries and precise specifications. This technology allows for the rapid prototyping of new designs, as well as the production of patient-specific implants that can be tailored to individual anatomical requirements.

Another exciting area of research is the integration of bioactive materials into polymer-based implants. These materials can promote tissue regeneration and healing, enhancing the performance and longevity of the implant. For example, bioactive coatings that release growth factors or antimicrobial agents can be applied to the surface of the implant to prevent infections and stimulate tissue growth. Additionally, researchers are exploring the use of hybrid materials that combine the benefits of polymers with those of other materials, such as ceramics or metals, to create implants with enhanced properties.

Conclusion

The use of polymers in medical implants represents a significant advancement in healthcare, offering numerous benefits in terms of biocompatibility, versatility, and functionality. From cardiovascular and orthopedic implants to dental and neurological devices, polymers have revolutionized the design and performance of medical implants, improving patient outcomes and quality of life. However, challenges related to biocompatibility, manufacturing, and regulatory approval still need to be addressed to fully unleash the potential power of polymers in medical implants.

As research and development in this field continue to progress, we can expect to see new innovations that further enhance the capabilities of polymer-based implants. Whether it is through the use of smart polymers, additive manufacturing, or bioactive materials, the future of medical implants holds great promise. By embracing these advancements and addressing the challenges, we can continue to innovate and improve the lives of patients around the world.

We invite you to leave a comment below and share your thoughts on the use of polymers in medical implants. Have you had any experiences with medical implants? What are your views on the future of polymer-based medical devices? Let’s continue the conversation and explore the exciting possibilities together.