Introduction

Polymethyl Methacrylate (PMMA), commonly known as acrylic or plexiglass, is a versatile and widely used material in various industries. Its clarity, durability, and biocompatibility have made it a material of choice in many medical applications, particularly in the field of prosthetics.

In the realm of craniofacial reconstruction and ocular prosthetics, Polymethyl Methacrylate (PMMA) plays a pivotal role in the creation of clear rigid orbital prostheses and prosthetic substructures. These devices are critical in restoring both function and aesthetics for patients who have suffered trauma, congenital defects, or disease.

In this post, we will explore the unique properties of Polymethyl Methacrylate, its application in the development of rigid orbital prostheses, and its importance in creating robust prosthetic substructures.

We will delve into the material’s characteristics, the manufacturing process, and the benefits it offers in the medical field. By the end of this article, you will have a comprehensive understanding of why Polymethyl Methacrylate (PMMA) is indispensable in the production of these essential medical devices.

The Unique Properties of Polymethyl Methacrylate

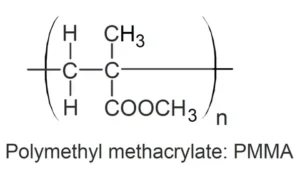

Polymethyl Methacrylate is a synthetic polymer derived from methyl methacrylate. It is known for its exceptional optical clarity, making it an ideal material for applications where transparency is crucial. Polymethyl Methacrylate (PMMA) is often used as a lightweight, shatter-resistant alternative to glass, but its properties go far beyond just visual applications.

✦ Optical Clarity and Transparency

One of the most defining features of Polymethyl Methacrylate is its optical clarity. PMMA allows for up to 92% light transmission, which is higher than many types of glass.

This makes it an excellent choice for rigid orbital prostheses, where the appearance of the eye socket needs to mimic natural tissue as closely as possible. The material’s transparency ensures that prostheses look natural, which is vital for the psychological and social well-being of patients.

✦ Durability and Resistance to Environmental Factors

Polymethyl Methacrylate (PMMA) is also known for its durability and resistance to various environmental factors, including UV light and weathering. This makes it suitable for both internal and external prosthetic applications.

In the case of rigid orbital prostheses, this resistance ensures that the prosthesis maintains its integrity and appearance over time, even when exposed to sunlight or other harsh conditions.

✦ Biocompatibility and Safety

Another critical factor in the use of PMMA for prosthetic substructures is its biocompatibility. PMMA is non-toxic and does not elicit significant immune responses, making it safe for long-term implantation in the human body.

This characteristic is particularly important for rigid orbital prostheses, which need to be both durable and safe for the patient.

✦ Ease of Manipulation and Customization

PMMA is relatively easy to mold and shape, allowing for high levels of customization. This is crucial in the production of prosthetic substructures, where each device must be tailored to the specific anatomical requirements of the patient.

The ability to precisely shape Polymethyl Methacrylate (PMMA) means that prosthetic devices can achieve a snug fit, improving comfort and functionality for the wearer.

Application of Polymethyl Methacrylate in Rigid Orbital Prostheses

Rigid orbital prostheses are used to replace the eye socket area in patients who have lost an eye or have severe damage to the orbital region. These prostheses must be both functional and aesthetically pleasing, and Polymethyl Methacrylate plays a crucial role in achieving these goals.

✦ The Role of PMMA in Orbital Prosthetics

In orbital prosthetics, PMMA is used to create a clear, rigid structure that mimics the natural appearance of the eye socket. The material’s optical clarity ensures that the prosthesis can replicate the look of the surrounding tissue, while its durability ensures that the prosthesis can withstand daily wear and tear.

✦ Customization and Precision in Orbital Prostheses

The ability to customize PMMA is particularly important in the field of orbital prosthetics. Each patient has unique facial anatomy, and the prosthesis must be tailored to fit perfectly. PMMA can be precisely molded to match the contours of the patient’s face, ensuring a natural and comfortable fit. This level of customization also helps to improve the prosthesis’s functionality, as a better fit translates to better movement and stability.

✦ Case Studies: Successful Applications of PMMA in Orbital Prostheses

There have been numerous successful applications of PMMA in the creation of rigid orbital prostheses. One notable example involves a patient who lost an eye due to trauma.

Using PMMA, a prosthetic eye socket was created that perfectly matched the patient’s remaining eye in both appearance and function. The result was a significant improvement in the patient’s quality of life, both in terms of appearance and confidence.

The Importance of Polymethyl Methacrylate in Prosthetic Substructures

Beyond its application in rigid orbital prostheses, Polymethyl Methacrylate is also a critical material in the construction of prosthetic substructures. These substructures serve as the foundation upon which various prosthetic devices are built, providing support and stability.

✦ Structural Integrity and Strength

PMMA’s strength and durability make it an ideal material for prosthetic substructures. These structures need to support the weight of the prosthesis and withstand the mechanical forces exerted during daily use.

PMMA’s high tensile strength ensures that prosthetic substructures remain intact and functional over time, reducing the risk of failure and the need for frequent replacements.

✦ Versatility in Prosthetic Design

The versatility of PMMA allows for a wide range of prosthetic designs. Whether creating a substructure for a limb prosthesis or a facial prosthesis, PMMA can be adapted to meet the specific needs of the patient. This adaptability is crucial in the development of prosthetic devices that are both effective and comfortable for the user.

✦ Enhancing Patient Outcomes

By providing a strong and stable foundation, PMMA-based prosthetic substructures contribute significantly to positive patient outcomes. Patients using prostheses with PMMA substructures often experience improved functionality and comfort, which can lead to better overall satisfaction with their prosthetic device.

The Manufacturing Process of PMMA-Based Prostheses

The manufacturing process of PMMA-based prostheses involves several steps, each of which is critical to ensuring the final product meets the required standards of quality and functionality.

✦ Material Preparation

The first step in the manufacturing process is the preparation of the Polymethyl Methacrylate material. This involves the polymerization of methyl methacrylate monomers into a solid, transparent material. The quality of the PMMA produced in this step is crucial, as it directly impacts the clarity and durability of the final prosthesis.

✦ Molding and Shaping

Once the PMMA material is prepared, it is then molded and shaped to create the desired prosthetic component. This step often involves the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies, which allow for precise control over the shape and dimensions of the prosthesis. The use of these technologies ensures that the final product fits perfectly and functions as intended.

✦ Finishing and Polishing

After the prosthetic component has been molded, it undergoes a finishing process to smooth out any rough edges and enhance its optical clarity. This step is particularly important for rigid orbital prostheses, where the appearance of the prosthesis must closely mimic natural tissue. The PMMA component is polished to a high shine, ensuring that it looks as natural as possible.

✦ Quality Control and Testing

The final step in the manufacturing process is quality control and testing. Each PMMA-based prosthesis is carefully inspected to ensure that it meets all relevant standards for safety, durability, and functionality. This step is critical in ensuring that the prosthesis will perform as expected and provide the patient with the best possible outcome.

Conclusion

Polymethyl Methacrylate is an essential material in the field of prosthetics, particularly in the creation of rigid orbital prostheses and prosthetic substructures. Its unique properties, including optical clarity, durability, biocompatibility, and ease of customization, make it an ideal choice for these applications.

The use of PMMA in prosthetics has led to significant advancements in both the functionality and aesthetics of these devices, improving the quality of life for countless patients.

As we have explored in this blog post, the application of Polymethyl Methacrylate in rigid orbital prostheses and prosthetic substructures is a testament to the material’s versatility and importance in medical applications.

Whether used to restore the appearance of an eye socket or to provide structural support for a prosthetic limb, PMMA continues to be a material of choice for medical professionals around the world.

If you have any thoughts or experiences related to the use of PMMA in prosthetics, we would love to hear from you! Please leave a comment below and join the conversation.