Introduction

The intersection of medical science and material engineering has given rise to innovative solutions that are transforming the way we approach healthcare. Among the most promising developments in recent years is the use of biodegradable polymers in Bone Repair and Tissue Engineering.

These materials, which are designed to safely degrade in the body after fulfilling their function, offer numerous advantages over traditional methods. As the demand for more effective and less invasive treatments grows, biodegradable polymers are becoming increasingly central to advancing medical practices, particularly in orthopedics and regenerative medicine.

In this post, we will explore how Bone Repair and Tissue Engineering can be significantly enhanced through the use of biodegradable polymers. We will discuss the role of these materials in promoting healing, their advantages over non-degradable alternatives, and how they are revolutionizing the field of regenerative medicine.

The main body of this article will be divided into four sections: the fundamentals of Bone Repair and Tissue Engineering, the role of biodegradable polymers, the advantages and challenges of using these materials, and future directions in this rapidly evolving field.

The Fundamentals of Bone Repair and Tissue Engineering

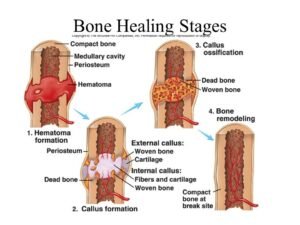

Bone Repair and Tissue Engineering are critical aspects of regenerative medicine, focusing on restoring the function and structure of damaged tissues. Traditional approaches to bone repair have relied heavily on methods such as bone grafting, where bone from a donor site is transplanted to the injured area. While effective, these methods come with significant drawbacks, including the risk of infection, donor site morbidity, and the limited availability of suitable graft material.

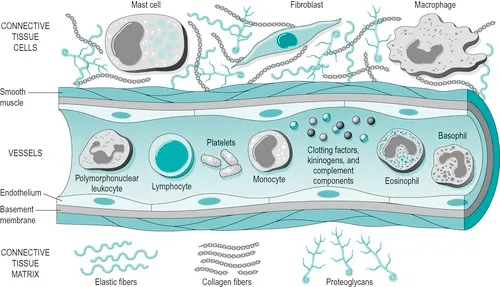

Tissue engineering, on the other hand, involves the creation of biological substitutes that can restore, maintain, or improve tissue function. This field combines principles from biology, engineering, and materials science to develop scaffolds that can support the growth of new tissue. These scaffolds are often seeded with cells and biologically active molecules to encourage the regeneration of damaged tissues.

In the context of Bone Repair and Tissue Engineering, the goal is to develop materials that can support bone regeneration while eventually being absorbed by the body, eliminating the need for additional surgeries to remove implants.

This is where biodegradable polymers come into play. These materials are designed to degrade safely in the body after they have served their purpose, making them an ideal choice for bone repair and other tissue engineering applications.

The Role of Biodegradable Polymers in Bone Repair and Tissue Engineering

Biodegradable polymers are synthetic or natural materials that can break down into non-toxic byproducts within the body. This degradation process is typically controlled by the body’s natural biological processes, ensuring that the polymers degrade at a rate that matches the healing process. In Bone Repair and Tissue Engineering, biodegradable polymers are used to create scaffolds that provide temporary support for the growth of new bone tissue.

One of the key advantages of using biodegradable polymers in Bone Repair and Tissue Engineering is their ability to be tailored to match the mechanical properties of natural bone. This ensures that the scaffold can provide adequate support during the healing process while gradually transferring the load to the regenerating tissue as it degrades. Additionally, biodegradable polymers can be engineered to release growth factors and other bioactive molecules over time, further promoting tissue regeneration.

Various types of biodegradable polymers have been explored for use in Bone Repair and Tissue Engineering, including polylactic acid (PLA), polyglycolic acid (PGA), and polycaprolactone (PCL). Each of these materials has unique properties that make them suitable for different applications. For example, PLA is known for its strength and rigidity, making it ideal for load-bearing applications, while PCL has a slower degradation rate, making it suitable for long-term applications.

In addition to their mechanical properties, biodegradable polymers can be processed into various forms, including fibers, films, and three-dimensional scaffolds. This versatility allows for the design of customized scaffolds that can be tailored to the specific needs of the patient and the injury. For example, scaffolds can be designed with pores of specific sizes to promote cell infiltration and vascularization, which are critical for successful tissue regeneration.

Advantages and Challenges of Using Biodegradable Polymers in Bone Repair and Tissue Engineering

The use of biodegradable polymers in Bone Repair and Tissue Engineering offers several significant advantages over traditional materials. One of the primary benefits is the elimination of the need for secondary surgeries to remove implants. This not only reduces the risk of complications but also improves patient outcomes by minimizing the overall number of surgical procedures required.

Another advantage of biodegradable polymers is their ability to promote natural healing processes. Because these materials can be engineered to degrade at a rate that matches the body’s healing process, they provide temporary support that gradually diminishes as the new tissue regenerates. This dynamic support system is more conducive to natural healing than static implants, which can interfere with the body’s ability to repair itself.

Biodegradable polymers also offer the potential for the localized delivery of therapeutic agents. By incorporating growth factors, antibiotics, or other bioactive molecules into the polymer matrix, it is possible to create scaffolds that not only support tissue regeneration but also enhance it by providing a sustained release of these agents at the site of injury.

This approach can significantly improve the effectiveness of Bone Repair and Tissue Engineering strategies, particularly in cases where infection or inadequate vascularization poses a risk to successful healing.

However, the use of biodegradable polymers is not without its challenges. One of the primary concerns is the potential for an inflammatory response to the degradation products. While most biodegradable polymers are designed to degrade into non-toxic byproducts, the rate and extent of degradation can vary depending on the material and the physiological environment. If the degradation products accumulate faster than the body can eliminate them, they may trigger an immune response that could hinder the healing process.

Another challenge is ensuring that the mechanical properties of the biodegradable polymer match those of the surrounding tissue. If the scaffold degrades too quickly or too slowly, it may not provide adequate support during the critical phases of healing. This requires careful consideration of the material’s properties and the specific requirements of the injury being treated.

Despite these challenges, ongoing research and development in the field of biodegradable polymers are continually improving the performance and safety of these materials. Advances in polymer chemistry and processing techniques are enabling the creation of more sophisticated scaffolds that can better mimic the properties of natural tissues and respond dynamically to the body’s healing processes.

Future Directions in Bone Repair and Tissue Engineering with Biodegradable Polymers

The future of Bone Repair and Tissue Engineering with biodegradable polymers looks promising, with several exciting developments on the horizon. One of the most significant trends is the integration of biodegradable polymers with other advanced technologies, such as 3D printing and nanotechnology.

3D printing, in particular, has the potential to revolutionize the way biodegradable polymer scaffolds are designed and manufactured. By using 3D printing technology, it is possible to create highly customized scaffolds that precisely match the geometry of the patient’s injury.

This level of customization can significantly improve the effectiveness of Bone Repair and Tissue Engineering strategies by ensuring that the scaffold fits perfectly within the injury site and provides optimal support for tissue regeneration.

Nanotechnology is another area of interest, as it offers the potential to create scaffolds with enhanced properties at the nanoscale. For example, incorporating nanoparticles into the polymer matrix can improve the mechanical properties of the scaffold, enhance its bioactivity, or provide additional functionalities, such as antimicrobial properties. These nanoscale modifications can further enhance the performance of biodegradable polymers in Bone Repair and Tissue Engineering.

Additionally, there is growing interest in the development of smart biodegradable polymers that can respond to changes in the physiological environment. These materials could be designed to release therapeutic agents in response to specific triggers, such as changes in pH or temperature, or to alter their degradation rate in response to the body’s healing process. Such smart materials could offer unprecedented control over the healing process and improve the outcomes of Bone Repair and Tissue Engineering treatments.

As research in this field continues to advance, it is likely that we will see the development of new biodegradable polymers with even greater potential for enhancing Bone Repair and Tissue Engineering. These materials will likely play a critical role in the future of regenerative medicine, offering new hope for patients with challenging injuries and conditions.

Conclusion

In conclusion, the use of biodegradable polymers in Bone Repair and Tissue Engineering represents a significant advancement in the field of regenerative medicine. These materials offer numerous advantages over traditional methods, including the elimination of secondary surgeries, the promotion of natural healing processes, and the potential for localized delivery of therapeutic agents. While there are challenges to be addressed, ongoing research and development are continually improving the performance and safety of biodegradable polymers.

As we look to the future, the integration of biodegradable polymers with advanced technologies such as 3D printing and nanotechnology promises to further enhance their capabilities and expand their applications. The development of smart materials that can respond to the body’s healing process offers exciting possibilities for the future of Bone Repair and Tissue Engineering.

We invite you to leave a comment below with your thoughts on how biodegradable polymers are shaping the future of regenerative medicine. Have you had any experiences with these materials, or are you interested in learning more? We’d love to hear from you!