Introduction

The field of medical implants has seen tremendous advancements, largely due to the development and application of advanced polymers. These materials play a crucial role in ensuring the success and longevity of implants, offering biocompatibility, durability, and functionality. However, selecting the right polymers for medical implants can be a complex process, involving considerations of mechanical properties, biocompatibility, and regulatory standards. This post aims to guide you through the essential factors to consider when choosing the right polymers for medical implants.

The Importance of Polymers in Medical Implants

Polymers have revolutionized the medical field, particularly in the development of implants. Their versatility allows for the creation of devices that can mimic the mechanical properties of natural tissues, provide controlled drug delivery, and promote tissue regeneration. Understanding why polymers are vital in medical implants helps set the stage for making informed decisions.

Biocompatibility and Safety

One of the primary reasons polymers are used in medical implants is their biocompatibility. This means they can interact with the human body without eliciting an adverse immune response. Biocompatible polymers are crucial for ensuring that implants do not cause inflammation, infection, or other complications post-surgery.

Versatility in Design

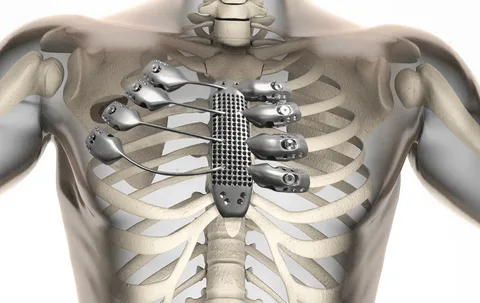

Polymers can be engineered to have specific properties tailored to different medical applications. This versatility allows for the creation of custom implants that can meet the unique needs of individual patients. From soft and flexible materials for cardiac stents to rigid and durable polymers for orthopedic implants, the possibilities are vast.

Key Considerations for Choosing Polymers for Medical Implants

When selecting polymers for medical implants, several factors must be taken into account to ensure the material’s suitability and effectiveness. These include mechanical properties, biocompatibility, degradation rate, and compliance with regulatory standards.

Mechanical Properties

The mechanical properties of a polymer are critical in determining its suitability for a particular medical implant. These properties include strength, elasticity, and fatigue resistance. For example, orthopedic implants require polymers that can withstand significant mechanical stress and mimic the properties of bone. Conversely, polymers used in soft tissue applications need to be flexible and elastic.

- Strength and Durability: The implant must withstand the mechanical forces exerted by the body without degrading or failing over time. Polymers like Polyetheretherketone (PEEK) are known for their high strength and durability, making them ideal for load-bearing implants.

- Elasticity: For applications such as cardiovascular stents, the polymer must be flexible and able to expand and contract without losing its structural integrity. Thermoplastic elastomers are often used for these applications due to their high elasticity.

Biocompatibility

Biocompatibility is a non-negotiable requirement for any material used in medical implants. The polymer must not only be non-toxic but also should not provoke an immune response. Polymers such as Polyethylene (PE) and Polydimethylsiloxane (PDMS) are widely used due to their excellent biocompatibility.

- Non-Toxicity: The polymer should not release any harmful substances into the body. This is particularly important for implants that are designed to remain in the body for long periods.

- Immune Response: The material should not cause inflammation or be rejected by the body. This can be ensured through rigorous biocompatibility testing during the development phase.

Degradation and Stability

The degradation rate of a polymer is another crucial factor. Some medical implants are designed to degrade over time, such as drug delivery systems or temporary scaffolds for tissue engineering. In contrast, others need to remain stable and functional for the patient’s lifetime, such as joint replacements.

Controlled Degradation

For implants that are intended to degrade, it is vital that this process is controlled and predictable. Biodegradable polymers like Polylactic Acid (PLA) and Polycaprolactone (PCL) are commonly used for applications where gradual degradation is desired.

- Predictable Degradation: The polymer should degrade at a rate that matches the healing process or drug delivery timeline. This ensures that the implant performs its intended function without causing harm.

- Byproducts of Degradation: The degradation products should be non-toxic and easily metabolized or excreted by the body.

Long-Term Stability

For permanent implants, the polymer must remain stable and functional for many years. Polymers such as PEEK and Ultra-High-Molecular-Weight Polyethylene (UHMWPE) are chosen for their long-term stability and resistance to wear and tear.

- Resistance to Wear: The material must withstand constant use and movement without significant degradation.

- Chemical Stability: The polymer should not react with bodily fluids or undergo unwanted chemical changes over time.

Regulatory Compliance

Ensuring that the chosen polymer meets regulatory standards is essential for the successful approval and commercialization of medical implants. This involves rigorous testing and documentation to demonstrate safety and efficacy.

Regulatory Bodies

Different regions have specific regulatory bodies that oversee the approval of medical devices. In the United States, the Food and Drug Administration (FDA) sets the standards, while in Europe, the European Medicines Agency (EMA) is responsible.

- FDA Approval: The polymer must meet the biocompatibility, mechanical, and safety standards set by the FDA. This includes preclinical testing, clinical trials, and post-market surveillance.

- CE Marking: In Europe, medical devices must obtain CE marking, indicating compliance with health, safety, and environmental protection standards.

Testing and Documentation

To obtain regulatory approval, extensive testing and documentation are required. This includes biocompatibility tests, mechanical tests, and clinical trials to ensure that the polymer is safe and effective for its intended use.

- Preclinical Testing: Laboratory tests and animal studies are conducted to evaluate the polymer’s properties and performance.

- Clinical Trials: Human trials are conducted to assess the safety and efficacy of the implant in real-world conditions.

- Post-Market Surveillance: Ongoing monitoring of the implant’s performance and safety after it has been released to the market.

Emerging Trends in Polymer Use for Medical Implants

The field of polymers for medical implants is continuously evolving, with new materials and technologies emerging that offer improved performance and new possibilities. Keeping abreast of these trends can help in making informed decisions about polymer selection.

Smart Polymers

Smart polymers, also known as stimuli-responsive polymers, can change their properties in response to external stimuli such as temperature, pH, or light. These materials offer exciting possibilities for medical implants, including controlled drug delivery and responsive tissue scaffolds.

- Controlled Drug Delivery: Smart polymers can release medication in response to specific triggers, providing targeted and controlled treatment.

- Responsive Scaffolds: These materials can support tissue regeneration and adjust their properties as the tissue heals.

Bioactive Polymers

Bioactive polymers interact with biological systems to promote healing and tissue integration. These materials can be engineered to release growth factors, support cell adhesion, and encourage tissue regeneration.

- Growth Factor Release: Bioactive polymers can release substances that promote cell growth and tissue healing.

- Tissue Integration: These materials can enhance the integration of the implant with the surrounding tissue, reducing the risk of rejection and improving outcomes.

Conclusion

Choosing the right polymers for medical implants involves a thorough understanding of the material properties, biocompatibility, degradation rates, and regulatory requirements. By considering these factors, medical professionals and researchers can ensure the development of safe, effective, and long-lasting implants that improve patient outcomes.

As the field continues to advance, staying informed about new materials and technologies will be crucial. The ongoing research and development in smart and bioactive polymers hold promise for even more innovative and effective medical implants in the future.

We hope this guide has provided valuable insights into selecting the right polymers for medical implants. We invite you to share your thoughts, experiences, and questions in the comments below. Your feedback helps us continue to provide relevant and useful information to our readers

1 Comment

Pingback: Tips to Ensure Longevity of polymer-Based Prosthetics - greenpolymershub.com