Introduction

Tissue engineering represents a groundbreaking field within biomedical research and medical practice, aimed at creating artificial organs and tissues to repair or replace damaged biological structures. A critical component in this innovative domain is the use of polymers, which provide the structural framework necessary for the growth and development of new tissue. This post explores how polymers are utilized in tissue engineering applications, highlighting their significance, types, and practical applications.

1. The Role of Polymers in Tissue Engineering

Polymers are versatile materials that can be engineered to have specific properties suitable for various tissue engineering applications. Their role is pivotal in providing a scaffold, which is essential for cell attachment, proliferation, and differentiation.

Biocompatibility and Biodegradability

Polymers used in tissue engineering must be biocompatible, ensuring that they do not induce an adverse immune response. Additionally, biodegradability is crucial as the scaffold must gradually degrade in the body, allowing the newly formed tissue to replace it. Polymers such as polylactic acid (PLA) and polyglycolic acid (PGA) are widely used due to their biocompatible and biodegradable properties.

Structural Support

The structural integrity of polymers is essential for maintaining the shape and mechanical properties of the engineered tissue. For example, in bone tissue engineering, polymers need to provide sufficient strength to support bone growth until natural bone replaces the scaffold. Composite polymers, which combine the properties of different materials, are often employed to enhance structural support.

2. Types of Polymers Used in Tissue Engineering

Several types of polymers are employed in tissue engineering, each with unique properties that make them suitable for specific applications.

Natural Polymers

Natural polymers, such as collagen, gelatin, and chitosan, are derived from biological sources. These materials are inherently biocompatible and often possess bioactive properties that promote cell adhesion and growth. Collagen, for example, is a major component of the extracellular matrix in the body and is widely used in tissue engineering to support the growth of various tissues, including skin and cartilage.

Synthetic Polymers

Synthetic polymers, like polylactic acid (PLA), polyglycolic acid (PGA), and polycaprolactone (PCL), are engineered to have specific properties tailored for tissue engineering applications. These materials can be designed to degrade at controlled rates and to have mechanical properties that match those of the tissue being replaced. PLA and PGA, in particular, are commonly used in the fabrication of scaffolds for bone and cartilage tissue engineering due to their strength and degradability.

Composite Polymers

Composite polymers combine the properties of natural and synthetic polymers to create materials with enhanced characteristics. These composites can be designed to mimic the complex structure and function of natural tissues more closely. For instance, hydroxyapatite (HA) is often incorporated into polymer matrices to create composite scaffolds for bone tissue engineering, providing both the mechanical strength of synthetic polymers and the bioactivity of natural bone minerals.

3. Techniques for Fabricating Polymer Scaffolds

The fabrication of polymer scaffolds is a critical step in tissue engineering, as the scaffold’s architecture directly influences cell behavior and tissue formation.

Electrospinning

Electrospinning is a versatile technique used to create nanofibrous scaffolds that closely mimic the extracellular matrix of natural tissues. This method involves applying a high voltage to a polymer solution to create fine fibers that are collected on a target surface. The resulting scaffolds have a high surface area-to-volume ratio, promoting cell attachment and proliferation.

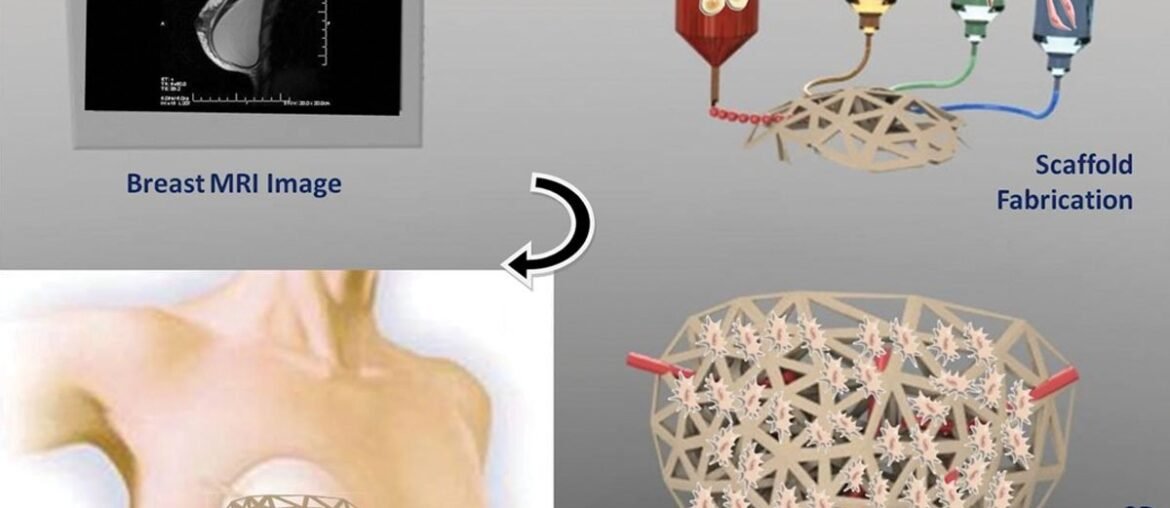

3D Printing

3D printing, also known as additive manufacturing, allows for precise control over the scaffold’s architecture, enabling the creation of complex, patient-specific structures. This technique involves layer-by-layer deposition of polymer materials to build up the scaffold. 3D printing is particularly useful for fabricating scaffolds with intricate internal architectures that can support vascularization and nutrient diffusion.

Solvent Casting and Particulate Leaching

Solvent casting and particulate leaching is a straightforward technique used to create porous polymer scaffolds. This method involves dissolving a polymer in a solvent, casting it into a mold with a porogen (a substance that creates pores), and then leaching out the porogen to leave behind a porous structure. The porosity of the scaffold can be controlled by adjusting the size and amount of the porogen, allowing for customization of the scaffold’s properties.

4. Applications of Polymer Scaffolds in Tissue Engineering

Polymer scaffolds have diverse applications in tissue engineering, ranging from skin and bone regeneration to the engineering of complex organs.

Skin Tissue Engineering

Polymer scaffolds are used in skin tissue engineering to treat wounds and burns. These scaffolds provide a temporary matrix that supports the growth of new skin cells and the formation of new tissue. Natural polymers, such as collagen and gelatin, are often used due to their bioactivity and ability to promote cell adhesion and migration.

Bone Tissue Engineering

In bone tissue engineering, polymer scaffolds provide structural support for the growth of new bone tissue. Composite polymers, incorporating materials like hydroxyapatite, are commonly used to mimic the mechanical properties of natural bone and to provide bioactive cues that promote bone formation.

Cartilage Tissue Engineering

Polymer scaffolds are also used in cartilage tissue engineering to repair damaged cartilage in joints. Synthetic polymers, such as PLA and PGA, are frequently used to create scaffolds that provide the necessary mechanical support while gradually degrading to be replaced by new cartilage tissue.

Organ Engineering

Advancements in polymer scaffold technology have also enabled the engineering of more complex organs, such as the liver and heart. These applications often require scaffolds with highly specific architectures to support the growth and function of multiple cell types. 3D printing is particularly useful in this context, allowing for the fabrication of scaffolds with intricate structures that can support vascularization and tissue integration.

5. Future Directions and Challenges

The field of tissue engineering continues to evolve, with ongoing research aimed at developing new materials and techniques to improve the performance of polymer scaffolds.

Advancements in Material Science

Researchers are exploring the use of novel polymers and composite materials to create scaffolds with enhanced properties. For example, the incorporation of growth factors and other bioactive molecules into polymer scaffolds can promote more effective tissue regeneration. Additionally, the development of smart polymers that respond to environmental stimuli, such as temperature and pH, offers new possibilities for dynamic and adaptive tissue engineering scaffolds.

Overcoming Immune Responses

One of the major challenges in tissue engineering is the potential for immune responses to polymer scaffolds. While many polymers are designed to be biocompatible, the body’s immune system can still react to foreign materials. Ongoing research aims to develop strategies to minimize these immune responses, such as coating scaffolds with anti-inflammatory agents or designing polymers that degrade into non-immunogenic byproducts.

Enhancing Vascularization

Effective tissue engineering requires the development of a vascular network to supply nutrients and oxygen to the growing tissue. Creating polymer scaffolds that support vascularization remains a significant challenge. Techniques such as 3D printing and the incorporation of angiogenic factors into scaffolds are being explored to address this issue.

Conclusion

Polymers play a crucial role in tissue engineering, providing the structural framework necessary for the growth and development of new tissues and organs. Through advancements in material science and fabrication techniques, researchers continue to improve the performance of polymer scaffolds, bringing us closer to the realization of fully functional engineered tissues and organs. The future of tissue engineering is promising, with the potential to revolutionize medicine and improve the quality of life for countless individuals.

We invite you to share your thoughts and experiences with tissue engineering and the use of polymers in this exciting field. Leave a comment below to join the discussion and contribute to the ongoing conversation about the future of biomedical innovation.

1 Comment

Pingback: Step by Step Guide to Prosthetics Design with Polymers - greenpolymershub.com